Knitted Wire Mesh Demister Mist Eliminator

Basic Info.

| Model NO. | YKFS-15 |

| Transport Package | Customized |

| Specification | hole size: 2x3mm, 4x5mm to 12x6mm |

| Trademark | Hebei Yongkun Metal Product |

| Origin | China |

| HS Code | 7314190000 |

| Production Capacity | 1000 M2/ Week |

Product Description

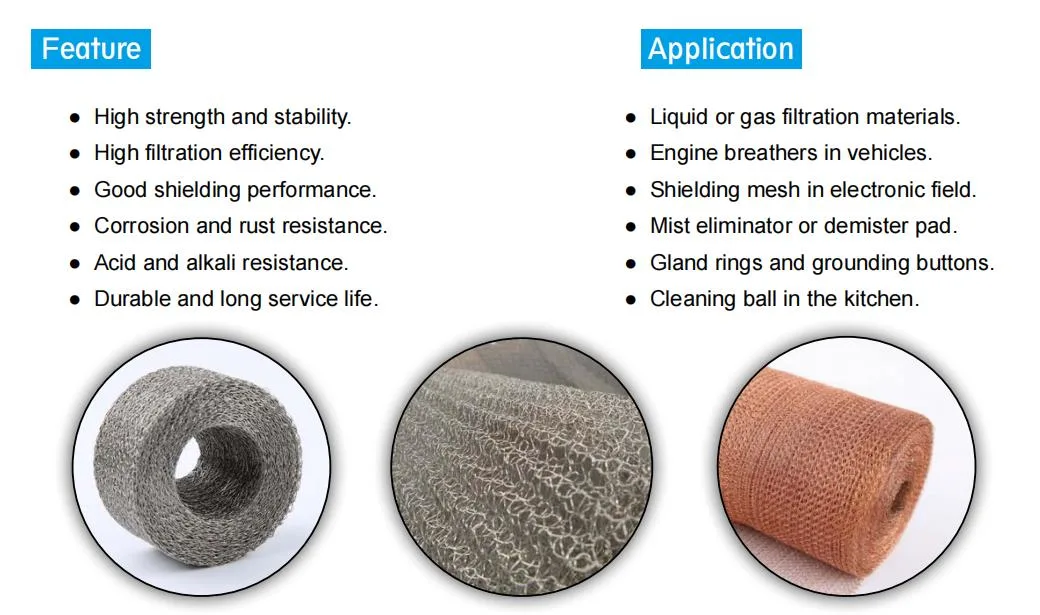

Knitted mesh is produced by the knitting machine, which is mainly made of stainless steel wire, copper wire, brass wire or polypropylene wire. And our knitted mesh products include knitted wire mesh roll, compressed knitted mesh, knitted mesh gasket and knitted mesh filter. Featured by high strength and perfect durability, knitted mesh is widely used as filtration material for liquid or gas separating and filtering. Besides, it's also can be used as engine breathers and shielding mesh and so on.

Knitted mesh The machine producing knitted wire mesh is similar to that machine making sweaters and scarves. Installing the various metal wires onto the round knitting machine and then we can get a continuous circle knitted wire mesh.

The knitted wire mesh can be made of round wires or flat wires. The round wires is the most commonly used type and the flat wire knitted mesh is commonly used in the special applications according to customers' requirements.

The knitted wire mesh can be made of mono-filament wires or multi-filament wires. The mono-filament knitted wire mesh features simple structure and economical, which is widely used in the common applications. The multi-filament knitted wire mesh has higher strength than the mono-filament knitted wire mesh. The multi-filament knitted wire mesh is commonly used in the heavy duty applications.

Features of knitted wire mesh

| Specification Material: stainless steel, copper, brass, nickle, polypropylene, alloy or galvanized iron wire. Manufacturing method: machine knitting. Type: flattened type, ginning type. Wire shape: round wire, flat wire. Wire number: single wire, double wires, three wires |

| Advantages High strength and integral rigidity. Perfect air penetrability. Abrasion and corrosion resistance. High and low temperature resistance. Easy to assemble, clean and replace. Durable and long service life. | Specification Material: stainless steel, copper, brass, nickle. Wire type: flat wire, round wire. Mesh type: flattened type, ginning type. Mesh shape: disc, ring, rectangular, trapezoid, column, cylinder, oval, strip or special shape. Packaging: packaged with brown paper first and then put into carton box. |

| Advantages High strength and stability. Corrosion and abrasion resistance. High temperature resistance. High performance of shielding. Durable and long service life. | Specificaiton Material: monel, aluminum, tinned copper steel, stainless steel wire. Wire diameter: 0.11 mm, 0.13 mm, and other diameters are available. Type of all metal gasket: common type, compressed type. Knitted mesh gasket style: |